Competence

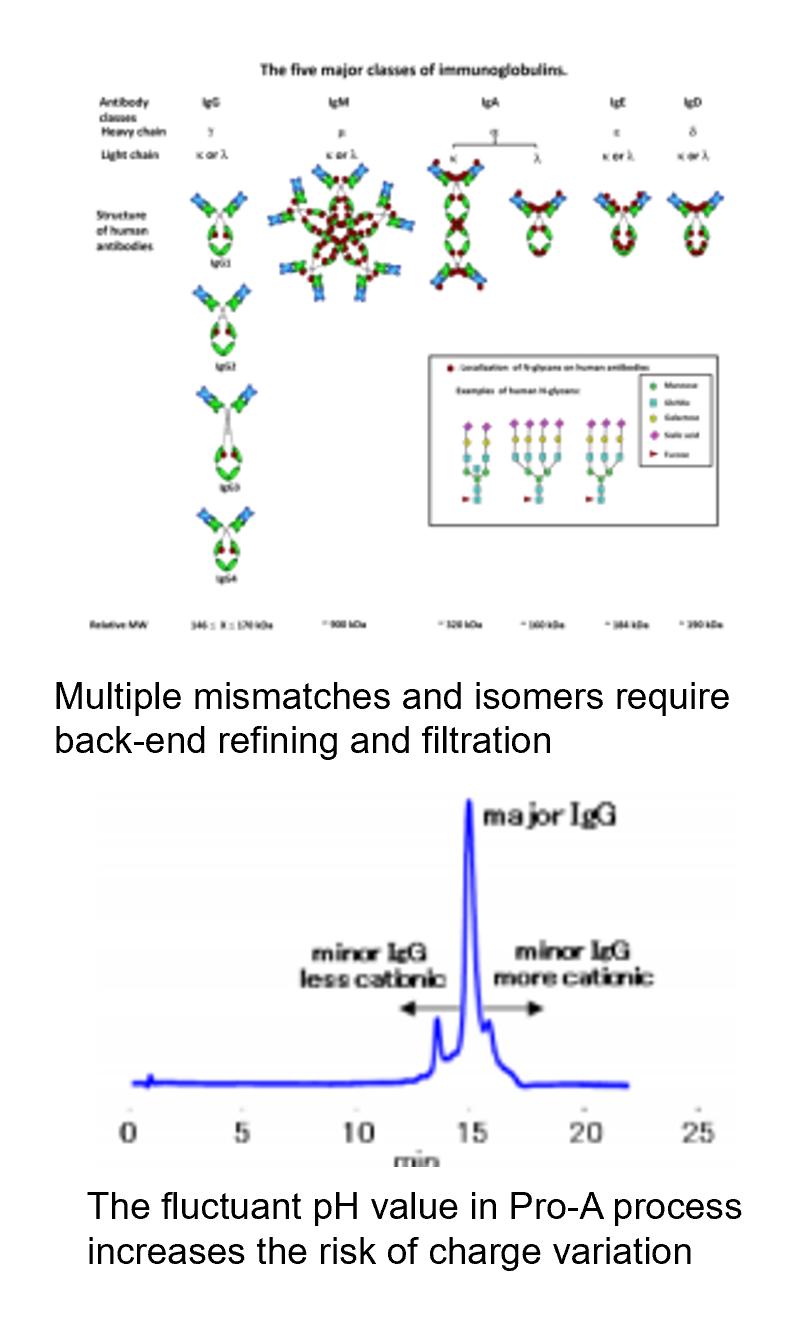

The HMFFE technology solution we use is based on a completely different and innovative technology path compared to traditional and Pro-A affinity high efficiency column chromatography. It is also very complementary to the traditional path.

HMFFE has obvious advantages in cost, efficiency and performance

HMFFE can act as the front-end/back-end process of Pro-A. It improves efficiency and reduces costs

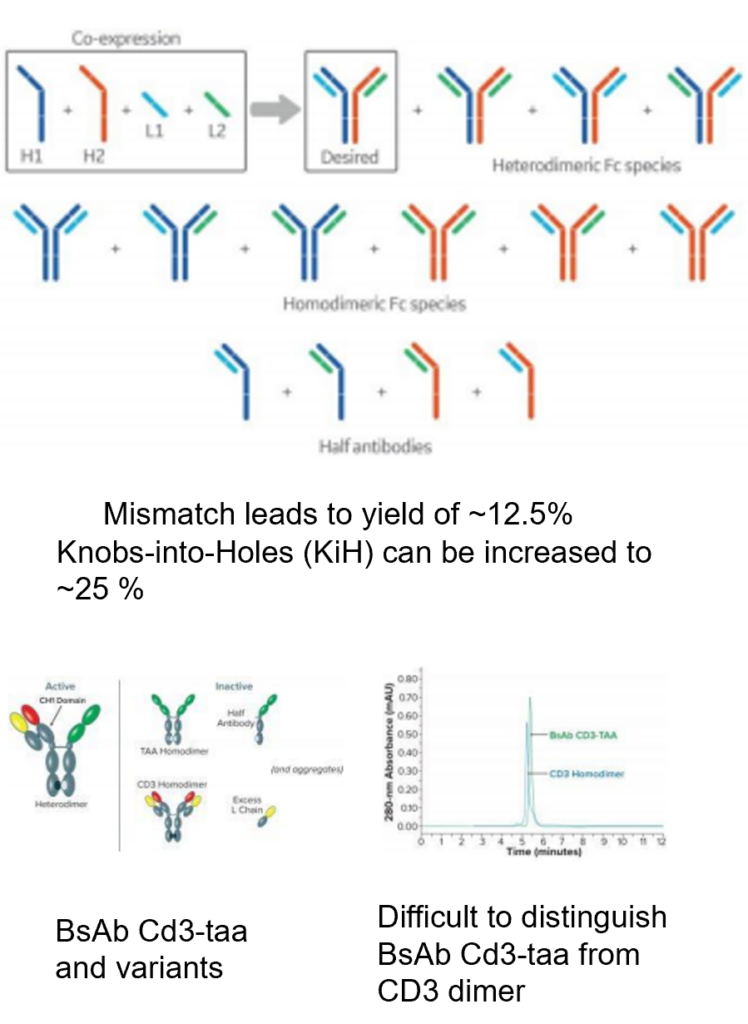

HMFFE enables direct purification of BsAb

HMFFE can reduce the difficulty of designing antibodies

Antibody therapy that have failed in due to limitation of the purification process may be reconsidered